Although specialty chemicals only account for 26% of the European chemical industry, they make a significant contribution to the overall European economy. This is largely due to the need for these substances in production in a wide variety of industrial sectors such as the construction, cosmetics, household, automotive and food industries.

titanium dioxide

Titanium dioxide (TiO2) is a very common industrial material that can be found as a basic ingredient or as an additive in a wide variety of products such as paint, sunscreen, toothpaste or food. The amount produced worldwide is also approximately 1.5 million tons, of which 60% is used for paints and coatings.

The size of the TiO2 particles is the most important factor for the properties of the final substance. For use in sunscreen, a particle size of 300nm is used, whereas transparent UV blockers require a significantly smaller particle size.

Due to the manufacturing process, the costs for smaller particles increase significantly. This can be the case up to a factor of 10.

Titanium dioxide for use as a white pigment

In order to use TiO2 particles as white pigments, they must be able to reflect visible light in the range from 440nm to 700nm.

Most of the light is scattered back by the particles when they have a size in the range of half the wavelength of the light. In this case, the desired particle size is 300nm.

The distribution of the differently sized particles has a decisive influence on the quality and color of the pigment to be produced. If the majority of the particles are below 300nm, the result is a blue cast, which is certainly desirable for laundry powder, but leads to reduced opacity for wall paints. If the particles are larger, the color shifts more towards brown and shiny surfaces can no longer be achieved.

The advantage of local sensors for process monitoring

In order to reduce the production time, a process must be used that detects the point in time at which the particle size has reached 300nm. Since the particle concentration and therefore the light transmission are very low, optical measurement techniques are ruled out from the outset.

Previously, material samples were taken from different process stages and their size was examined in diluted form using UV spectrometers. However, this measurement technique is subject to severe limitations due to the delayed feedback of results and the PH sensitivity of the diluted samples.

Process ultrasonic spectroscopy

Ultrasonic spectroscopy describes the reaction of a material when excited by a weak ultrasonic source. This method has the following advantages:

- Non-destructive, non-intrusive

- also for non-transparent materials

- for solid and liquid substances

- easy sample handling without manual intervention

- Use over a wide frequency range

Ultrasonic waves are high-frequency mechanical waves whose propagation characteristics depend on the thermo-physical properties of the respective medium.

Rheology describes the measurement of time- and temperature-dependent flow and deformation properties of liquids and deformable materials under the influence of an external force.

ITS has with that U2S developed an ultrasonic spectroscope that can record the distribution and concentration of particles of different sizes by measuring these properties.

The following characteristics of materials can be determined with the system:

- Density measurement and concentration of individual phases of mixed liquids and suspensions

- Rheological determination of liquids and soft substances by phase velocity measurement

- Changes in the attenuation profile due to changes in material composition such as particle size

- Relaxation phenomena in biological materials and soft solids

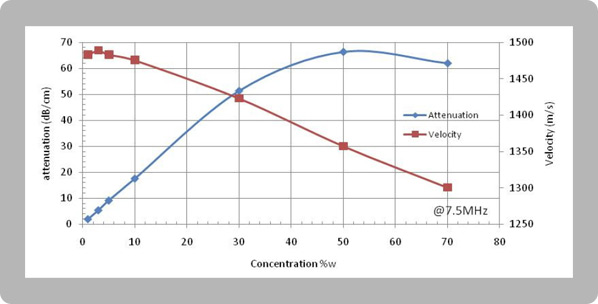

Concentration dependence of titanium dioxide

The concentration dependence of titanium dioxide for a particle size of 300 nm was determined using a concentration profile. For this purpose, samples with different concentrations were used (1, 3, 5, 10, 30, 50 and 70%), which lead to different measured values on the diagram.

Summary

Ultrasonic spectroscopy makes it possible to determine the size, distribution and concentration of the particles in highly concentrated particle samples in real time.