Laser Applications in Metrology

1. introduction: The importance of lasers in measurement technology

Lasers have revolutionized measurement technology and enable precision at a level that is unattainable with conventional methods. Their properties such as high coherence, low divergence and a precisely adjustable wavelength make them indispensable. CW lasers and tunable lasers in particular are widely used in precision metrology.

A key advantage of lasers is their versatility. Applications such as interferometry use lasers for high-precision measurements of distances and angles. They play a key role here, as they are indispensable for many industries.

In addition, laser safety eyewear ensures safety when working with powerful laser systems. This is particularly important in industrial environments, where safe working conditions are a top priority.

Due to the continuous development of laser technology, new Laser Applications in Metrology that raise precision and efficiency to a new level.

2. basics of laser technology for metrology applications

Structure and Function of a Laser

A laser (Light Amplification by Stimulated Emission of Radiation) generates light that is highly coherent, monochromatic and focused in a narrow beam. This is achieved by amplifying photons in an active medium that is excited by an energy source. The mirrors of the resonator, which amplify and precisely align the light, are crucial for this.

Important parameters: Wavelength, power and coherence

The wavelength of a laser determines which applications it is suitable for. For example, infrared lasers are often used in spectroscopy and material analysis. The power of a laser, measured in watts, varies from milliwatts for laboratory applications to several kilowatts for industrial cutting applications.

Coherence is a decisive parameter in measurement technology, as it enables the interference capability of light and thus supports applications such as interferometry.

laser classes and safety standards

Lasers are divided into classes according to how dangerous they are, from class 1 (harmless) to class 4 (potentially dangerous to skin and eyes). Safety standards such as the use of laser safety goggles are essential, especially with powerful lasers, in order to protect users. Safe use is an essential component of all Laser Applications in Metrology, especially with high-power lasers.

3. Interferometry: Precise Laser Applications in Metrology

How an interferometer works

An interferometer uses the principle of light interference to measure distances, angles or surface profiles with extremely high precision. The system splits the laser light into two beams that travel different paths. It recombines the beams and generates interference patterns that reveal the measured variable. Michelson interferometers in particular are known for their accuracy in precision measurement technology. Interferometers are one of the most important Laser Applications in Metrologyas they deliver highly precise results.

Applications: Distance, angle and surface measurements

Interferometry is used in various areas of measurement technology:

- Distance measurement: Ideal for the precise determination of small distances, for example in semiconductor production.

- Angle measurement: In optical systems to make precise adjustments.

- Surface measurements: For analyzing surface roughness or flatness, for example in the production of optical components.

For example, the combination of interferometers and powerful cw lasers enables particularly precise measurements in industry and research.

CW / quasi-CW laser

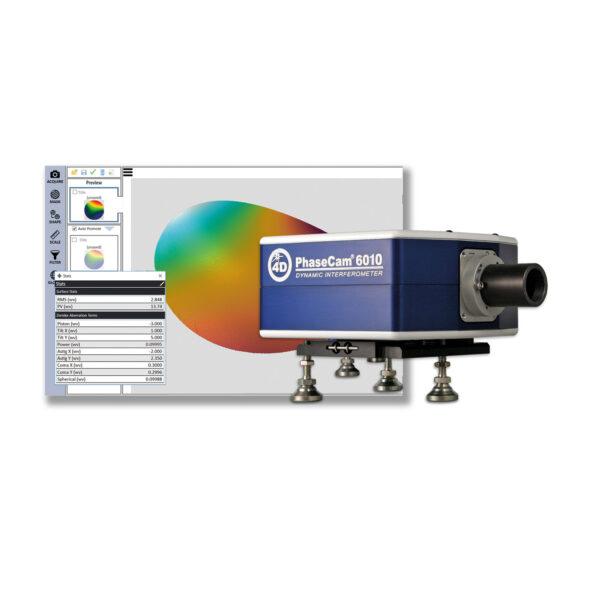

Example: Twyman-Green interferometer: structure and areas of application

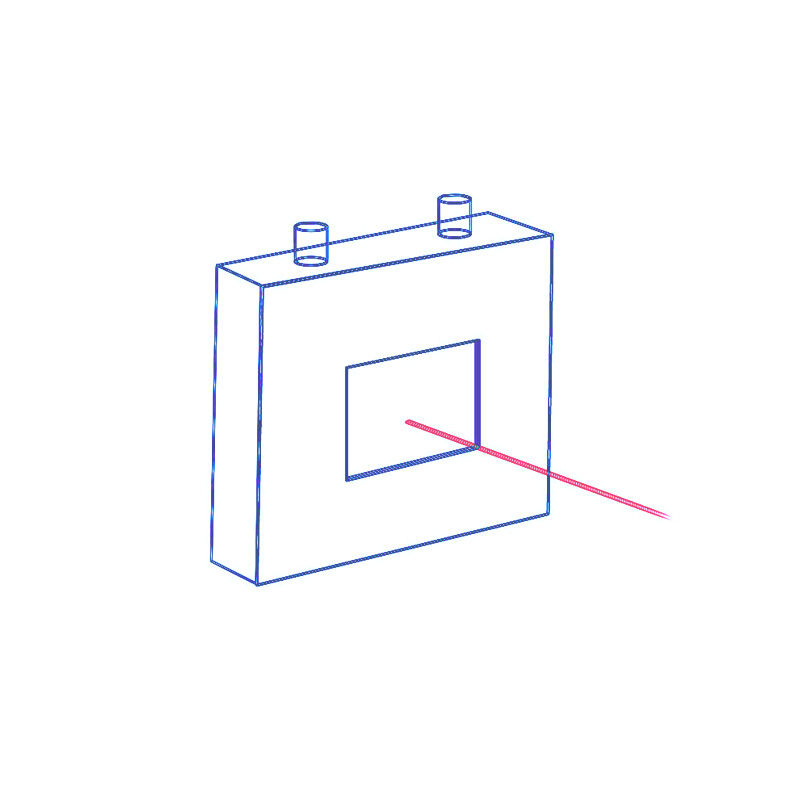

The Twyman-Green interferometer is a further development of the Michelson interferometer and is used specifically for testing optical components. Similar to the Michelson interferometer, a laser beam is split into two beams. One of the beams is directed at the object to be tested (e.g. a lens or a mirror), while the other serves as a reference beam. When the beams are recombined, an interference pattern is created that makes deviations in the shape or quality of the optical surface visible.

This interferometer is particularly useful in the manufacture and quality control of optical systems, as it can detect tiny defects and distortions. It is often used in conjunction with cw lasers, which are known for their high stability.

Advantages of the Twyman-Green interferometer

- High precision: Ideal for measuring the smallest surface deviations.

- Flexibility: Can be adapted for different optical components such as lenses or mirrors.

- Easy integration: Can be integrated into automated measuring systems and thus enables efficient quality control.

4. spectroscopy: advanced laser measurement technology for molecular analyses

Raman Spectroscopy: Making Molecular Structures Visible

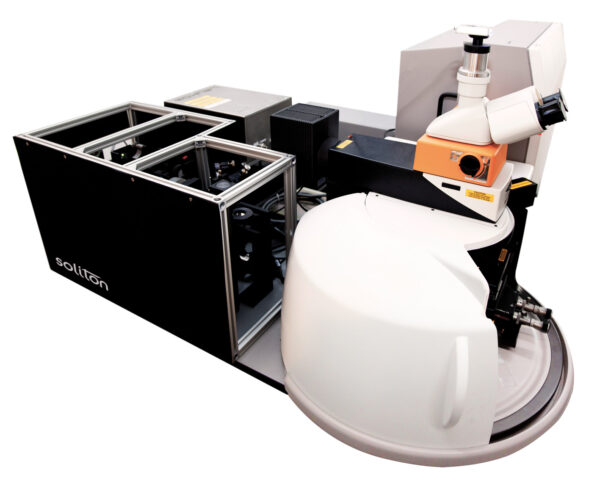

Raman spectroscopy is a widely used method for analyzing molecular structures. A laser beam is directed at a sample and the backscattered light is examined. The Raman shift - small frequency changes caused by the interaction of light with molecular vibrations - allows chemical compositions and bonds to be precisely identified.

This technique is particularly advantageous as it enables minimally invasive analyses and samples only require minimal preparation. Tunable lasers are ideal for Raman spectroscopy as they can be flexibly adapted to different classes of molecules.

Near-infrared spectroscopy (NIR): Versatile applications

NIR spectroscopy analyzes the absorption behavior of materials in the near infrared range (800-2500 nm). This method is ideal for determining chemical and physical properties as it can penetrate deep into samples. It is frequently used in the food and agricultural industries, but also in pharmaceutical research, e.g. to determine moisture or to analyze complex mixtures.

Pulsed lasers can be used in NIR spectroscopy to improve sensitivity and measurement speed, especially when analyzing volatile substances.

CARS (Coherent Anti-Stokes Raman Spectroscopy): Advanced Raman technology

CARS is an extension of Raman spectroscopy that uses coherent light to amplify chemical signals. This technique enables fast and highly sensitive analysis of molecules and is used, for example, in biology and materials research. The use of pulsed lasers also allows dynamic processes to be observed in real time.

LIBS (Laser-Induced Breakdown Spectroscopy): Elemental analysis by laser

The LIBS technique uses a pulsed laser to ionize the surface of a sample. The resulting plasma emits light whose spectrum reveals the chemical composition of the sample. LIBS is a fast and non-destructive method that is particularly valued in environmental analysis and materials testing. The technology therefore represents one of the most innovative Laser Applications in Metrologyas it works non-destructively and efficiently.

5. Laser triangulation: An indispensable laser application in measurement technology

principle of laser triangulation

Laser triangulation is a precise method of distance measurement in which a laser beam is projected onto a surface and the reflected light is recorded by a detector. By evaluating the angle between the laser source, reflected light and detector, the distance can be calculated. This technique is particularly effective for measurements on irregular or moving surfaces.

The high accuracy and speed make laser triangulation ideal for applications in industrial production and quality control. Compact cw lasers are used here, which impress with their high stability and long service life.

Applications in industrial quality assurance

Laser triangulation is frequently used in quality assurance to check dimensions, surface profiles or edge positions. Examples of applications include

- Component measurement: Precise measurement of length, width and height of workpieces.

- defect detection: Identification of surface defects such as dents or cracks.

- Process monitoring: Real-time control in production lines to ensure dimensional accuracy.

The ability to record measurement data quickly and without contact makes this technology particularly efficient and economical. Laser beam guidance components are often used to optimally adjust the light guidance.

Advantages: Speed and accuracy

Laser triangulation offers numerous advantages over conventional measurement techniques, such as

- High measuring speed: Ideal for real-time applications in manufacturing processes.

- Excellent accuracy: Even the smallest deviations can be detected, which increases the quality of the products.

- Non-contact measurement: Particularly suitable for sensitive or movable surfaces.

These properties make laser triangulation indispensable for modern production environments. It is one of the most efficient and flexible Laser Applications in Metrology. In combination with a power meter, the laser power can be monitored to ensure optimum measurement results, for example.

Laser Power Meters and Laser Energy Meters

6. Laser scanner: 3D measurement technology and other laser applications

Structure and Function of a Laser Scanner

A laser scanner uses precisely controlled laser beams to capture objects in three dimensions. The laser beam scans the surface of an object, while sensors record the reflected light signals. The captured data is converted into a detailed 3D model that is used for analysis, design optimization or manufacturing processes.

With their ability to scan large objects quickly and accurately, laser scanners are essential in industries such as architecture, engineering and manufacturing. Modern devices such as the Nanocam also offer ultra-high resolution for nanometer-precise scanning.

The Nanocam: Precision at nano level

The Nanocam from 4D Technology sets new standards in 3D measurement technology. With its ability to capture surfaces with a resolution in the nanometer range, it is ideal for inspecting and analyzing the finest structures. This laser scanner technology is used in the semiconductor industry, materials research and the production of high-precision components.

A key advantage of the Nanocam is its user-friendliness and compactness. Thanks to the integration of state-of-the-art laser technology, it delivers high-precision data that can optimize production processes and minimize errors. This product demonstrates how precise and advanced modern Laser Applications in Metrology can be.

Applications in 3D measurement technology

Laser scanners like the Nanocam are used in a variety of applications:

- Quality control: Precise measurement of components to ensure dimensional accuracy and surface quality.

- Research and Development: Creation of detailed 3D models for material studies and prototype development.

- Reverse Engineering: Reconstruction of existing objects for adaptations or post-production.

Thanks to their versatility and precision, laser scanners make an important contribution to increasing efficiency and product quality in modern manufacturing. Products such as the Nanocam set new standards in 3D measurement technology and offer companies decisive competitive advantages. (Further information on the NanoCam: https://4dtechnology.com/products/optical-profilers/nanocam-hd/)

7. Innovative Technologies: The Future of Laser Applications in Metrology

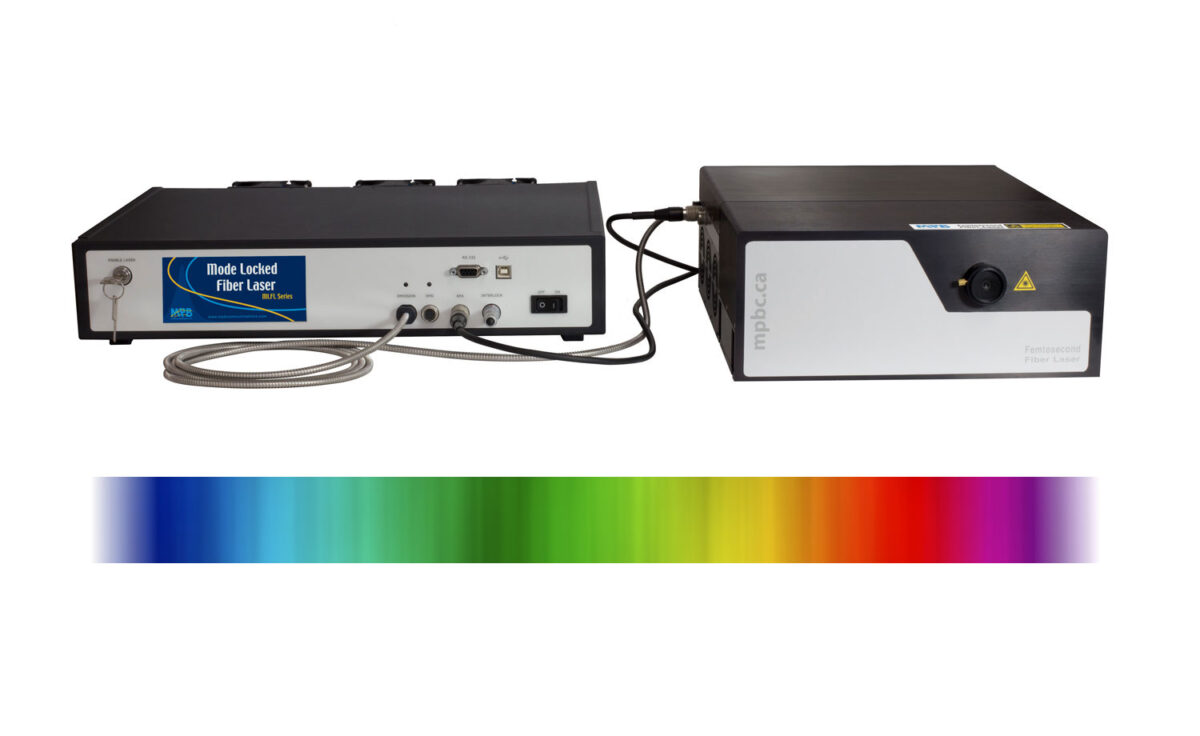

Femtosecond lasers: precision in the nanometer range

Femtosecond lasers are among the most advanced technologies in metrology. These lasers emit ultra-short light pulses that last just a few femtoseconds (1 femtosecond = 10-¹⁵ seconds). This allows extremely precise measurements and material processing to be carried out without causing thermal damage.

Applications of femtosecond lasers include:

- Materials research: Analysis and processing of sensitive materials such as glass or biological samples.

- Micromachining: Engraving and cutting with the highest precision.

- Nonlinear spectroscopy: Investigation of molecular structures using highly sensitive measurement methods.

Femtosecond lasers are increasingly being used in science and industry, especially in areas where maximum precision is required.

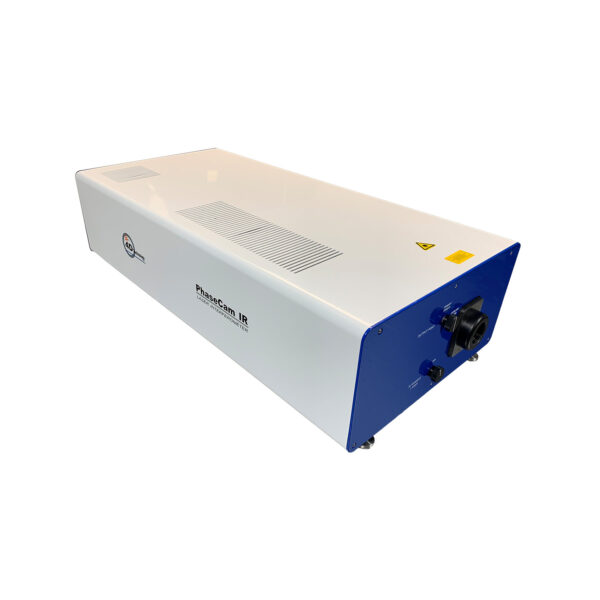

Optical coherence tomography (OCT): medicine and materials testing

Optical coherence tomography (OCT) uses coherent light to create high-resolution cross-sectional images of materials or biological tissue. This technology is widely used in medicine, e.g. in ophthalmology to analyze the retina, but also in material testing to examine layer structures.

With its ability to measure non-destructively and in real time, OCT offers enormous added value for industrial and scientific applications. Laser beam guidance components play a central role in precisely directing the light beams.

Nonlinear optical effects: New possibilities for measurements

Non-linear optical effects open up new possibilities in measurement technology. These effects occur when laser light interacts with high intensity in special materials. Examples of this are

- Harmonic generation: Doubling or tripling the frequency of light to extend the measuring range.

- Self-focus: Increasing the light intensity in a medium for specific measurement applications.

Such effects are increasingly used in materials research and spectroscopy, for example in combination with modern laser systems such as tunable or pulsed lasers.

8. selection and calibration: optimal lasers for metrology applications

What to look for when choosing a laser

The choice of the right laser measuring device depends heavily on the planned application. Parameters such as

- Wavelength: Different materials and applications require specific laser wavelengths (e.g. infrared for materials research, visible light for optical applications).

- Operating mode: cw lasers are ideal for continuous wave applications such as interferometry, while pulsed lasers are suitable for dynamic processes such as LIBS spectroscopy.

- Performance and stability: Precision applications require powerful and stable lasers that deliver consistently reproducible results

Calibration and maintenance: ensuring long-term precision

Regular calibration of laser measuring devices is essential to ensure precise and reliable results. This includes checking the laser wavelength, beam intensity and alignment of optical components. Calibration steps can be:

- Comparison with certified standards to ensure accuracy.

- Adjustment of the laser beam guide to ensure optimum focusing.

- Check the optical components to detect soiling or wear.

Proper maintenance not only increases the service life of the devices, but also the efficiency of their use. Laser safety goggles and other safety devices should also be checked regularly.

Certifications and quality standards

When purchasing a laser measuring device, care should be taken to ensure that it complies with the relevant international standards, e.g:

- ISO 9001: Quality management systems for devices and processes.

- IEC 60825: Safety of laser products.

- ISO/IEC 17025: Requirements for the competence of calibration and testing laboratories.

Certified devices not only guarantee safety, but also the reliability of the measurement results. This is particularly important in industries such as medical technology and semiconductor production.

9. advantages of laser applications for your company

Increased efficiency through precise measurement technology

Laser-based measurement technologies enable highly precise and reliable measurements that conventional methods often cannot achieve. This accuracy leads to shorter throughput times, less rework and more efficient production overall. For example, cw lasers or tunable lasers can be integrated into automated manufacturing processes to deliver continuously accurate results.

Companies benefit not only from the improved quality of their products, but also from the greater speed and flexibility offered by laser-based systems.

Cost reduction through durable and low-maintenance systems

Laser-based measurement technologies are known for their durability and low maintenance requirements. Modern laser systems, such as pulsed lasers or interferometers, are designed to work reliably even under demanding conditions. This significantly reduces operating costs as less frequent maintenance cycles and spare parts are required.

In addition, the non-contact nature and high measurement speed of lasers minimize production downtime and material loss, which can lead to significant savings in the long term.

Competitive advantages through innovative technologies

The integration of modern laser technologies into measurement technology gives companies a decisive advantage over their competitors. Precise and innovative applications such as spectroscopy (e.g. Raman or NIR spectroscopy) or interferometry make it possible to open up new markets and set higher quality standards.

Products like the Nanocam or power meters offer companies tools with which they can meet even the most demanding customer requirements. By using such technologies, companies can not only optimize their production, but also strengthen their brand image as technological pioneers.

10 Conclusion and further resources

Summary: Key findings

Laser Applications in Metrology have revolutionized the way precision and efficiency are achieved in industry, research and development. From interferometry to spectroscopy to laser triangulation, laser-based systems offer unparalleled accuracy, speed and versatility.

The use of products such as cw lasers, tunable lasers, interferometers or high-precision laser scanners such as the Nanocam companies can not only increase their productivity, but also tap into new markets.

Further resources

If you would like to find out more about laser technologies and their diverse applications, we invite you to discover our other content:

Adaptive Optics with Spatial Light Modulators

stylus method

measuring surface roughness

Laser Applications in Metrology

Glossary of Measurement Technology: The 50 Most Important Terms

RMID: Identification and Analysis of Raw Materials

Find out more about our products and discover how our technologies can improve your Laser Applications in Metrology can optimize. Our team of experts is at your disposal. Contact us for a personal consultation and find out how our products can boost your success.