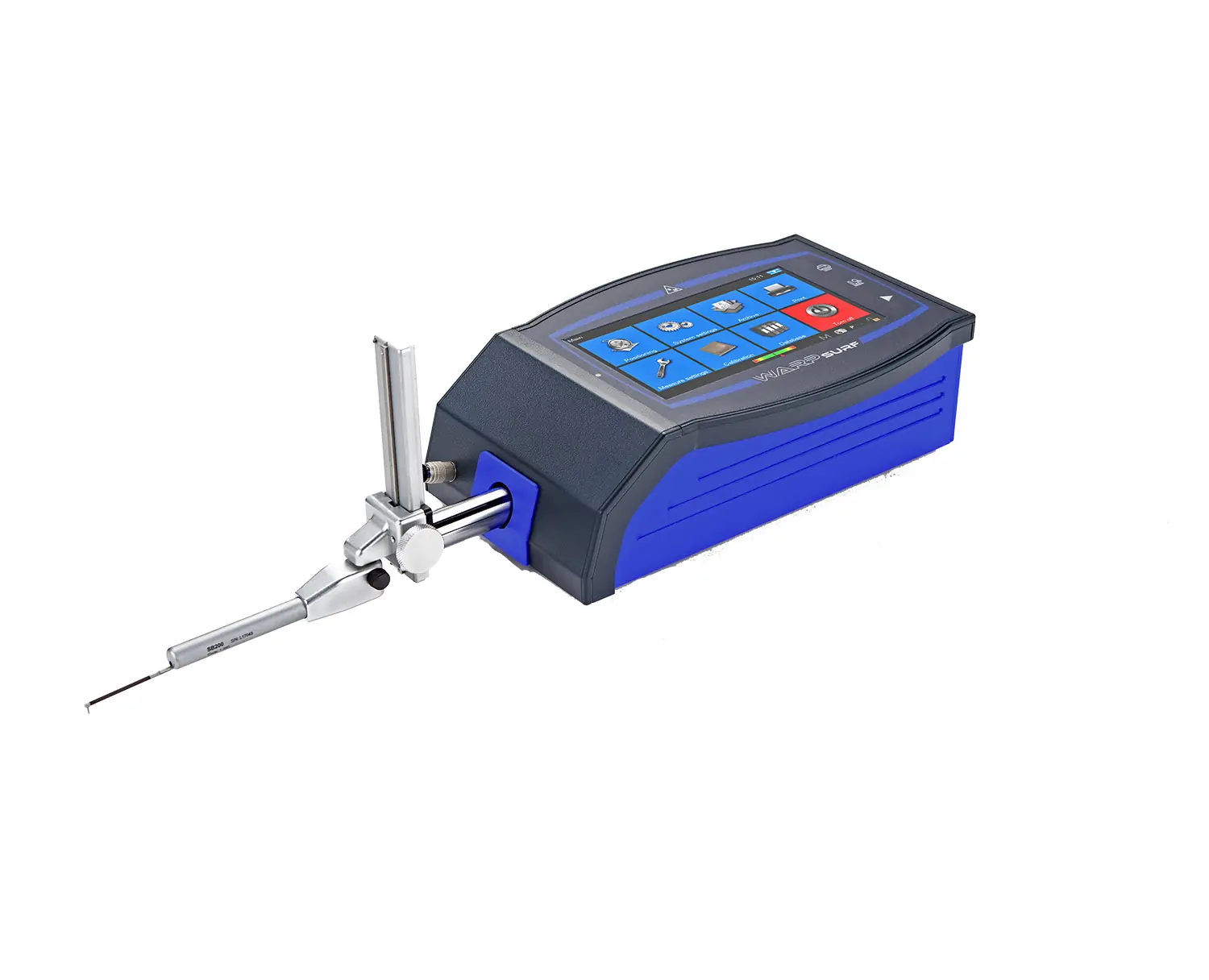

The WARPsurf Roughness and Contour Meter is a groundbreaking instrument for surface analysis. With its all-in-one design, it enables complete roughness and profile analysis using just one portable device. In addition, the 7-inch color touchscreen and user-friendly icon interface make it as easy to use as a smartphone, even for first-time users.

The integrated 1 GHz microprocessor ensures smooth operation and fast processing of complex profiles. The compact and handy WARPsurf also has a micrometric positioning system with a 110 mm stroke. In addition, it has an innovative, interchangeable probe system with a magnetic holder, which makes positioning easier even on large workpieces.

The integrated safety function, with magnetic arm holder, offers reliability and prevents damage. Images can be saved or reports printed in PDF format via the USB interface. There is also the option of connecting a standard desktop printer to print directly. In addition, For more detailed analysis, the device can be connected to a computer via Bluetooth to use the advanced Profile Studio software.

Finally, there is the option to connect the WARPsurf to the company network via Wi-Fi to save measurement data and print reports wirelessly.

Application examples

Examples of applications for the roughness and contour measuring device include the detection of roughness and waviness on standard components as well as inside complex components with edges that are difficult to access with standard probes. A variety of standard probes or self-definable probes are used. Holes up to a diameter of 2 mm are also easily accessible.

In contour mode, any contour up to a height of five millimeters can be traced and evaluated. This means that radii, edges, steps or even errors of any kind can be scanned. Examples of this are threads, grooves or height profiles, there are no limits, everything with a surface can be measured.