Precise particle size measurement - directly in the closed container

Non-invasive analysis with SR-DLS technology

Particle size is a decisive quality parameter in many pharmaceutical products. Previously, such analyses required time-consuming sampling, dilution and laboratory tests - with risks for sterility, reproducibility and loss of time. With the innovative SR-DLS technology (Spatially Resolved Dynamic Light Scattering) InProcess-LSP offers a solution that Particle sizes directly in the closed container measures - Fast, precise and completely contactless.

How does SR-DLS work?

The technology combines Dynamic light scattering (DLS) with Low Coherence Interferometry (LCI). Light signals are scattered in the product and analyzed based on their temporal fluctuations. This allows the Diffusion coefficient and from this the particle size exactly.

Through the Complete backscatter geometry (180°) and a depth-resolved measurement particles can be detected at different depths in the container - even with curved surfaces or cloudy formulations.

This optical method works Completely container-independent and is suitable for Glass, plastic and flexible packaging, without opening or changing the sample.

Flexible system for any packaging

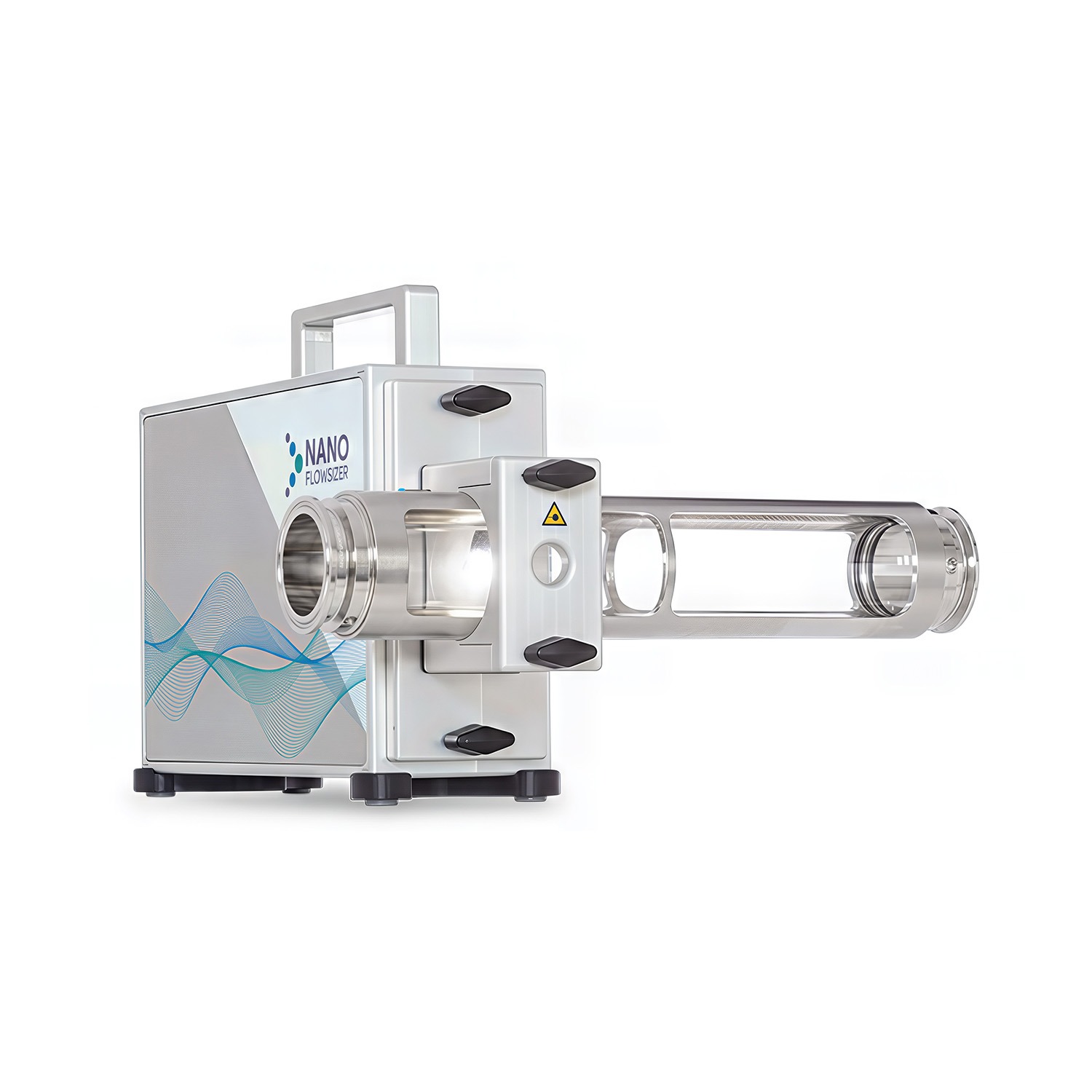

The NanoFlowSizer has a modular design and adapts to a wide variety of packaging types.

- Vial modules enable measurements in standard glass vials and syringes.

- Clamp modules offer maximum flexibility for irregular or larger vessels.

Thanks to this adaptability Particle sizes in sterile prefilled syringes, Infusion bags or large-volume plastic containers just as reliably as in laboratory vials.

Even with very cloudy emulsions - for example in propofol formulations - the system delivers Reproducible and characteristic measurement results, which are known as Fingerprint of product quality can serve.

For modern process and quality control

With the SR-DLS technology, particle size analysis Part of the production process. It allows the Direct quality assessment of the end product, without detours via the laboratory. In this way Shorter production times, Risks minimized and Increased process reliability become.

Whether glass vials, plastic bottles, infusion bags or prefilled syringes - the NanoFlowSizer offers Maximum precision and flexibility for your application.