Precise monitoring of tablet coatings in real time

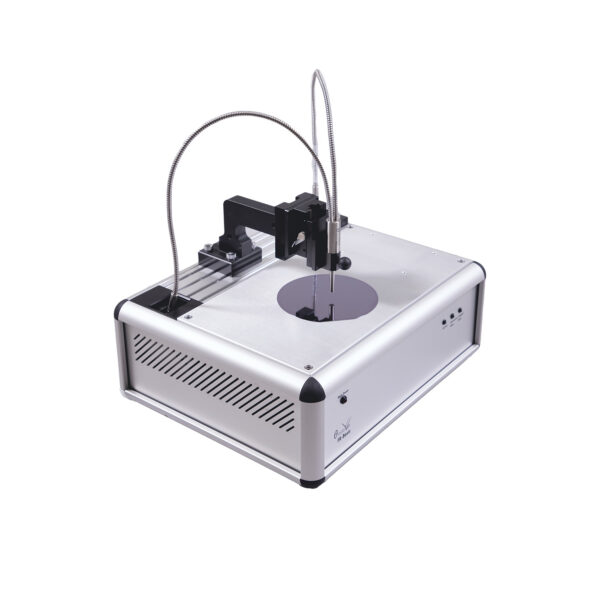

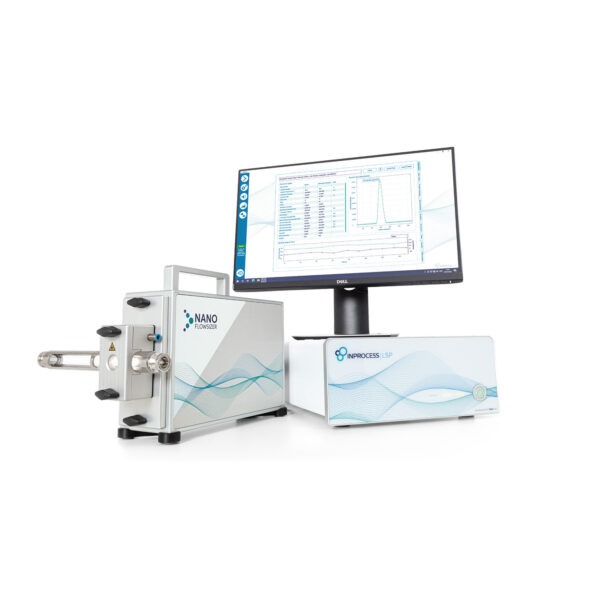

The tablet coating measuring systems from SOLITON enable precise control of the coating thickness during the production process. Continuous measurement allows deviations to be detected and corrected immediately, resulting in consistent product quality and reduced reject rates.

Technical properties

The systems use modern optical measurement technology to determine the thickness of the coating non-destructively. They work without contact and deliver measurement results in real time. The robust design allows them to be used directly in production facilities, even under demanding conditions. Integration into existing control systems is uncomplicated.

Advantages of tablet coating measurement

Precise monitoring significantly improves the coating quality. The system helps to reduce material costs as overcoating is avoided. At the same time, process reliability is increased as faulty batches are detected at an early stage.

Areas of application

The measuring systems are used in the pharmaceutical industry, particularly in the production of tablets with functional or aesthetic coatings. They are also suitable for research and development in order to optimize new coating processes.

Contact and advice

For detailed technical information and a solution tailored to your production processes, we will be happy to provide you with an individual offer. Visit our product page. Further technical information on pharmaceutical process analysis can be found at SPIE - The International Society for Optics and Photonics.