Handheld defect detection with 3D precision – InSpec & InSpec XL

Mobile surface analysis for industry and quality assurance

The handheld defect detection with Soliton's InSpec system offers a precise and flexible solution for detecting and measuring surface defects directly on site. Originally developed for the aviation industry, the device enables the direct measurement of defects, radii, and angles on component surfaces—all without the need for complex replication or disassembly.

With a lateral resolution of up to 4 µm and a vertical accuracy of 4 µm, the InSpec system detects even the smallest surface deviations. In addition, the integrated software automatically identifies defects such as scratches, cracks or dents and creates detailed 2D and 3D representations for comprehensive analysis.</span>

Versatile applications and easy handling

The handheld design of the InSpec allows it to be used in various areas such as production, incoming goods inspection or in the field. Thanks to optional accessories such as mirror sets and flexible brackets, even hard-to-reach areas can be measured precisely. In addition, the system is suitable for use with robots, which enables automated testing in manufacturing processes.

The InSpec XL expands the application possibilities with a larger measuring field of 15 mm × 15 mm and a maximum defect depth of up to 9 mm, ideal for the analysis of larger components.</p>

News

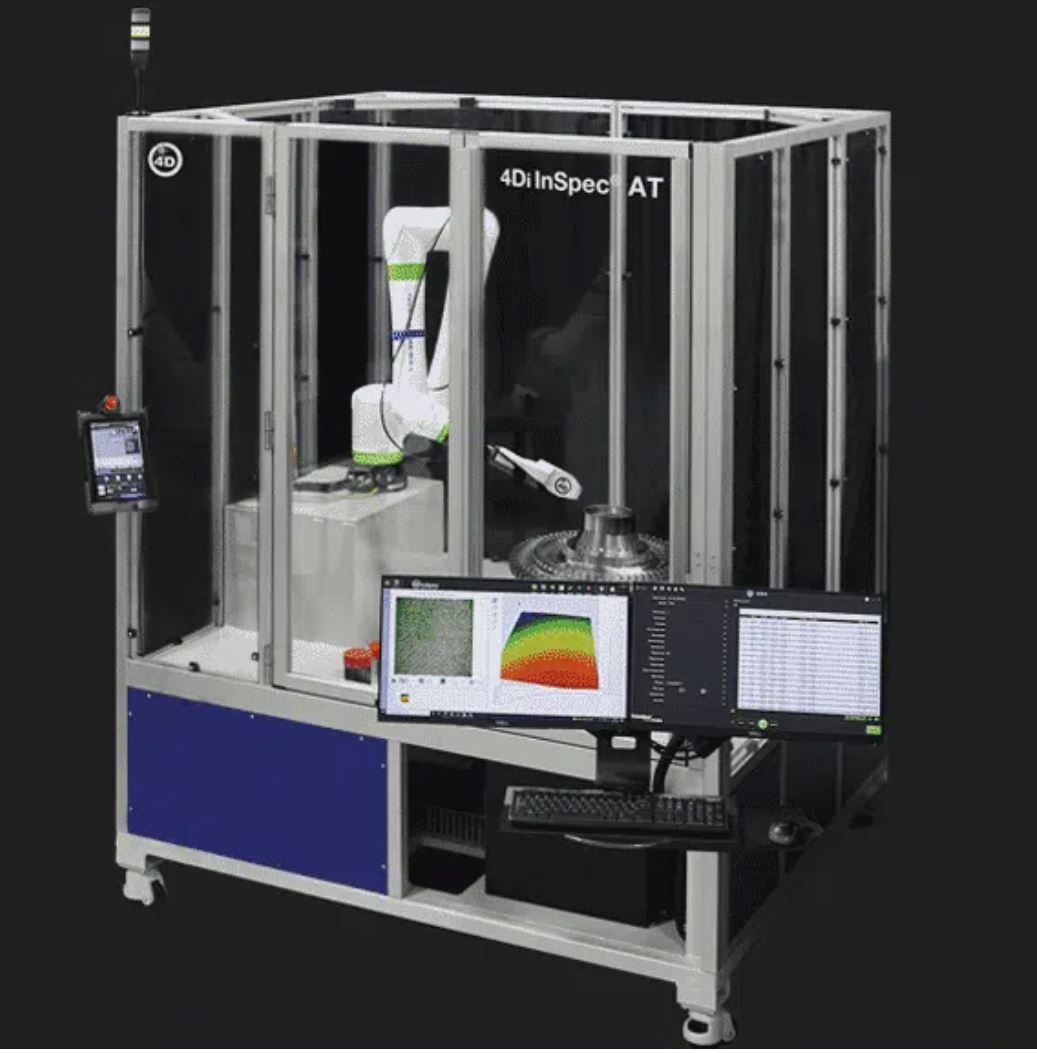

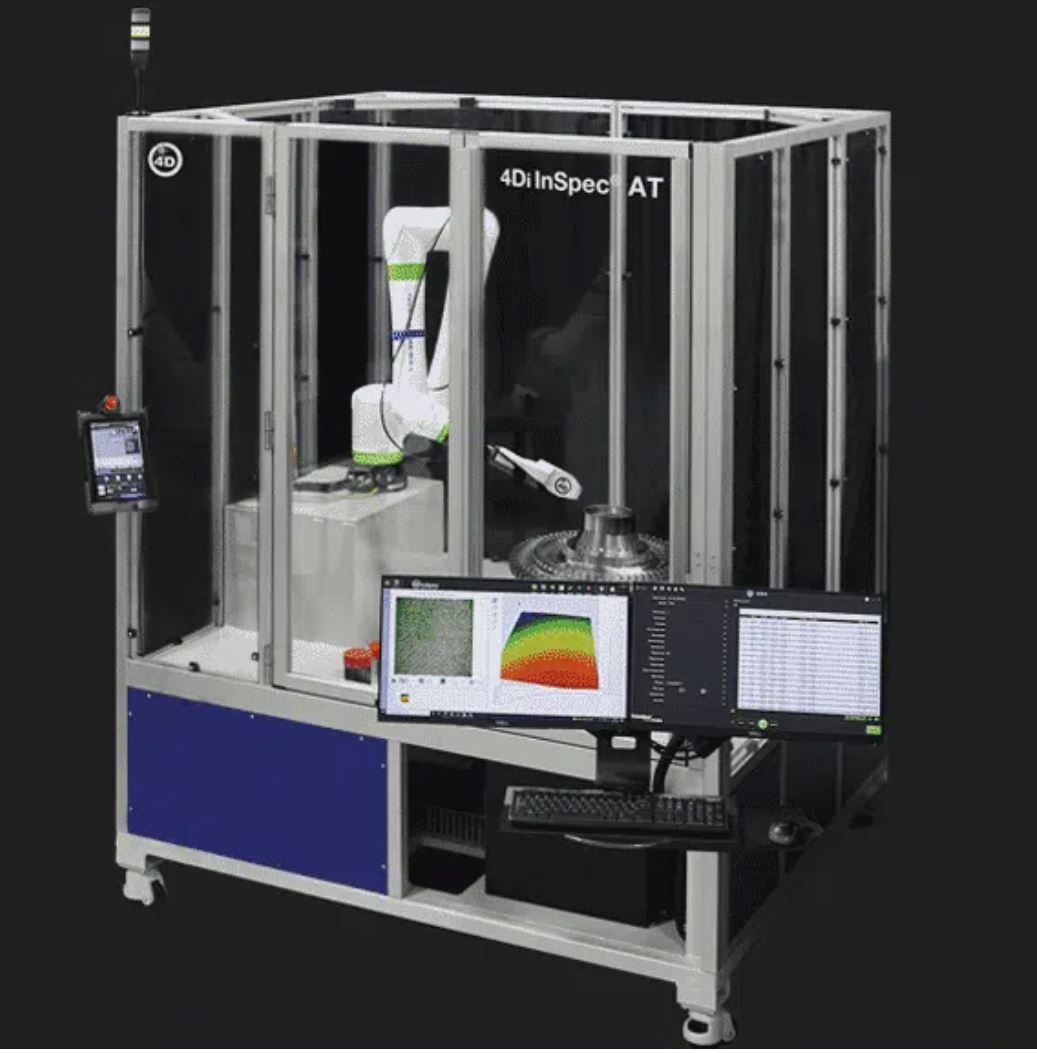

4D Technology installs high-throughput, high-resolution automated edge break system at an aerospace engine manufacturer

4D Technologies, a wholly owned subsidiary of Onto Innovation Inc., has installed and commissioned a 4Di InSpec AT automated inspection system at a leading aerospace engine manufacturer. The system will move into full production next quarter.

“We developed the 4Di InSpec AT in collaboration with leading aerospace engine manufacturers to dramatically improve the measurement process,” said Erik Novak, Managing Director of 4D Technologies. “By improving measurement accuracy, the system significantly reduces rework and scrap caused by the rejection of actually good parts. Additionally, it improves inspection throughput by several orders of magnitude, saves critical labor, and provides rapid production feedback to improve part quality.”

Aircraft and engine components can have dozens of critical specifications for chamfers and curves to optimize performance and life. These numerous characteristics can only be measured manually, which is time-consuming. Areas that are difficult to access must be replicated for measurement, which further increases cycle time.

The 4Di InSpec AT system combines the industry-leading 4D InSpec surface measurement device with a collaborative robot for non-contact measurement of chipped edges, chamfers and fillets, as well as surface defects such as pits, scratches and dents on aerospace parts. With measurements taking only seconds, as opposed to many minutes or hours with manual methods, the automated system significantly increases measurement throughput and workload. The ability to measure features in difficult locations further improves inspection quality.

“The 4D InSpec surface measurement device has become established in the aerospace and MRO (rework/repair) industries,” said Novak. “The fact that leading manufacturers are now using this technology in inline production underlines its great value to the industry.”

Highlights of the 4Di InSpec AT include:

- Measure dozens of edge break features, chamfers, radii and defects in minutes instead of days.

- Non-contact 3D measurement with a resolution in the micrometer range.

- Patented vibration-insensitive technology enables measurements in the workshop.

- Specially developed software flags measurements that are out of specification and automatically remeasures the locations.

- Integration with Fanuc CRX 5iA or CRX10iA/L collaborative robots.

- Ability to measure inner and outer wave characteristics using folding mirrors and compact probe design.

- Optional rotary table for improved throughput.

- Numerous safety features including a fully enclosed cell.

Link to article