The innovative calorimeter from LaserPoint can deliver laser powers of up to 12 kW measure precisely. Thanks to research into new materials and a sophisticated thermal design for heat dissipation, this device is able to reliably measure high power.

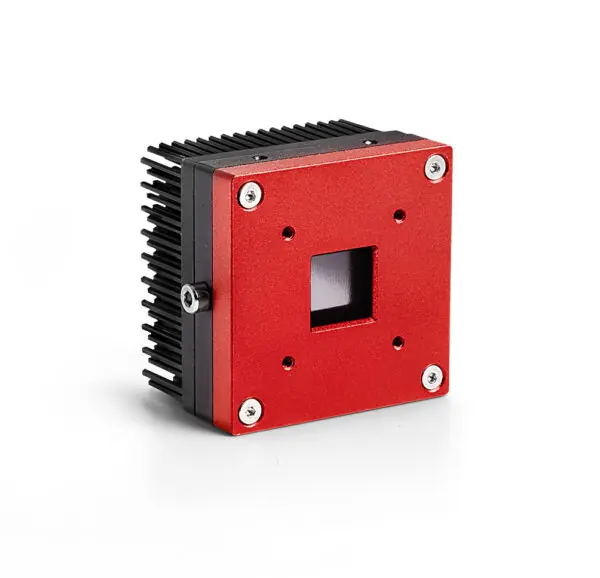

The calorimeter is characterized by its extremely compact and lightweight design, which makes it much more manageable than alternative instruments in the same performance class. In addition, it does not require defocusing optics in the absorption cavity, which reduces installation effort.

With a linearity of ± 2 % up to the full scale value and a calibration accuracy of ± 5 %, which on PTB/NIST standards The detector guarantees the highest measurement precision because it is traceable. This means you can rely on the accuracy and reliability of your measurements.

In addition, the calorimeter is equipped with the latest technology that offers a fast response time and high stability. The advanced sensor technology allows even the smallest fluctuations in performance to be reliably recorded. This is particularly important in applications where precision and consistency are crucial. In addition, the device is designed to be user-friendly, so that installation and operation can be carried out intuitively and saves time. This means you can concentrate on your core tasks while the calorimeter ensures accurate and reliable measurements.

Our calorimeter are ideal for industrial and scientific applications where precise measurement of high laser power is crucial. Trust in our expertise and optimize your laser applications with our advanced measurement solutions.

If you have any further questions about the systems, please feel free to send us a non-binding inquiry. Further information about the products and all technical data sheets for each variant can be found here: Laserpoint.eu.