Process ultrasonic spectroscopy

The chemical industry plays a crucial role in the European economy. Although specialty chemicals only account for 26% of production, they are indispensable in numerous sectors, including construction, cosmetics, automotive and food. Titanium dioxide (TiO2) in particular is an essential material, the properties of which depend heavily on the particle size. This is where the Ultrasound spectroscopy as an innovative method for process monitoring.

Titanium Dioxide and its Applications

Titanium dioxide is a widely used material that is used both as a main ingredient and as an additive in products such as paints, sunscreens, toothpastes and food. In addition, around 1.5 million tonnes are produced worldwide every year, of which around 60% are used in paints and coatings. This is precisely where ultrasonic spectroscopy can come into play.

The particle size of TiO2 is a decisive factor for the properties of the final product. While sunscreens require particle sizes of around 300 nm, transparent UV blockers require much smaller particles. The smaller the particles, the higher the production costs - these can be up to ten times higher.

TiO2 as a white pigment:

In order for TiO2 to be used as a white pigment, the particles must reflect visible light in the range of 440 nm to 700 nm. The optimal particle size for this reflection is around 300 nm. However, differences in particle size affect the color quality. If the majority of the particles are smaller than 300 nm, a blue tint is created, which is desirable for detergents, but reduces the opacity of wall paints. Larger particles, on the other hand, lead to a brown color and a loss of shine.

Challenges in Process Monitoring

The production of TiO2 requires precise process control to achieve the optimal particle size of 300 nm. Since optical measurement techniques are unusable due to the low light transmittance of TiO2 samples, samples have so far been taken, diluted and analyzed using UV spectrometers. However, this process is time-consuming, error-prone and highly dependent on the pH of the samples, which means the use of ultrasonic spectroscopy.

Ultrasound Spectroscopy: An Efficient Solution

Ultrasonic spectroscopy therefore offers an innovative alternative to real-time particle size determination. In this method, a material is excited by high-frequency mechanical waves, the response of which in turn depends on the thermo-physical properties of the medium. In addition, this method is:

- Non-destructive and non-intrusive

- Suitable for solid, liquid and opaque substances

- Easy to handle without manual intervention

- Applicable over a wide frequency range

The ITS The U2S technology developed by us uses ultrasonic measurements to measure particle size, distribution and concentration in highly concentrated suspensions and is an example of a sophisticated application of ultrasonic spectroscopy.

Applications of Ultrasound Spectroscopy

The U2S system allows the determination of the following material properties:

- Density and concentration of mixed liquids and suspensions

- Rheological properties such as flow behavior and deformation

- Changes in material composition due to particle size changes

- Relaxation phenomena in biological materials and soft solids

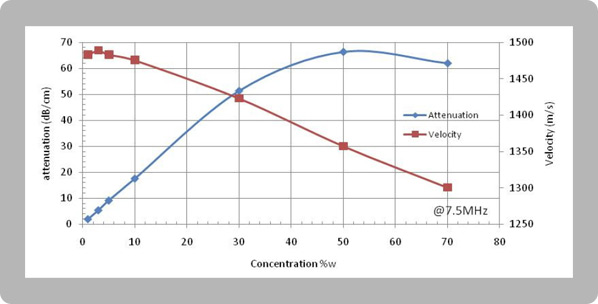

An example application is the Concentration dependence of titanium dioxide. The graph shows samples with different concentrations (1 %, 3 %, 5 %, 10 %, 30 %, 50 %, 70 %). The results show how particle size and concentration affect the material properties, which illustrates why continuous monitoring by ultrasonic spectroscopy is necessary.

Summary

Ultrasonic spectroscopy is therefore revolutionizing process monitoring in the chemical industry. This method can also be used to determine particle size, distribution and concentration in real time - even in highly concentrated samples. In addition, this reduces production time, improves product quality and minimizes costs. Finally, U2S technology offers a reliable, efficient and versatile solution for the requirements of modern industrial processes.

More articles:

- Types of spectroscopy

- CARS spectrometer: Innovation in Raman spectroscopy

- LIBS spectroscopy: Revolutionary technology for elemental analysis

- Coherent Anti-Stokes Raman Scattering with Comparison to Raman Spectroscopy