light transmission in the fiber laser

The transmission of light through optical fibers has had a lasting impact on many areas of life. They make crucial contributions, particularly in telecommunications, process engineering, fiber optic sensors, spectroscopy and medical diagnostics. Another important area is laser technology, in which fiber laser increasingly replacing other types of lasers. Due to their versatility and efficiency, they have become an indispensable tool in numerous industries.

light transmission in fibers

Typical optical fibers consist of a core surrounded by a cladding with a lower refractive index. Total reflection guides the light in the core, which enables low-loss transmission over long distances. In laser technology, a special property of the fibers is also used: doped quartz fiber cores can amplify light and serve as an active laser medium.

The most common dopings and their typical emission lines are:

- Erbium: 1550 nm

- ytterbium: 1030 nm

- neodymium: 1064 nm

- thulium: 1500 nm

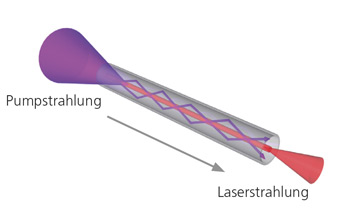

In order to pump the light efficiently into the doped fibers, double-cladding fibers are used. The pump light runs in an additional cladding around the core and ensures a long interaction path. This technology is a crucial step in the further development of laser technology.

How fiber lasers work

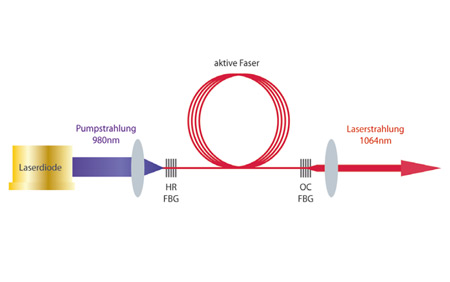

A conventional solid-state laser consists of a pump diode, a laser crystal and a mirror resonator. In the fiber laser, a doped fiber replaces the laser crystal, and so-called fiber Bragg gratings (FBGs) replace the mirrors. These gratings selectively reflect the desired laser wavelength in the core fiber and offer several advantages:

- High stability, since no adjustment of the mirrors is required.

- High efficiencybecause up to 70 % of the pump light is converted into laser light.

- High gain, made possible by the long interaction distance along the fiber.

Fiber amplifiers and their performance

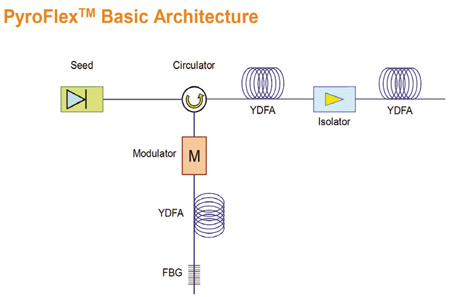

Fiber lasers often use a combination of seed lasers and fiber amplifiers, such as EDFAs (Erbium-Doped Fiber Amplifiers) or YDFAs (Ytterbium-Doped Fiber Amplifiers). These amplifiers amplify the laser signal in stages and allow flexible adaptation to different applications.

The maximum power is limited by the damage threshold of the power amplifier fiber:

- single-mode fibers: up to 10 kW

- multimode fibers: up to 50 kW

To avoid feedback, Faraday isolators are used, which increase the stability of the system.

high-power and low-power lasers

Fiber lasers can be divided into high-power and low-power lasers:

- low-power lasers are used in biotechnology and telecommunications. Frequency-doubled fiber lasers from MBP Communications generate wavelengths in the visible range that are ideal for fluorescence microscopy and flow cytometry. These lasers provide precise excitation for various fluorescent markers.

- high-power laser are used primarily in material processing. Applications include cutting and welding metals. A notable example is IPG's fiber laser with a beam power of 18 kW.

Pulsed fiber lasers and MOPA technology

For applications that require short light pulses, pulsed fiber lasers are used. The MOPA technology (Master Oscillator Power Amplifier) offers significant advantages. A seed laser defines the pulse duration, while the fiber amplifiers amplify the energy without changing the pulse duration. This creates precise and repeatable pulses, which are particularly advantageous in material processing and medical applications.

Limitations of Fiber Lasers

Despite their many advantages, fiber lasers require careful design to work reliably:

- damage threshold of the power amplifier: High laser power can damage the fiber.

- ASE (Attenuated Spontaneous Emission): Causes undesirable radiation effects.

- Nonlinear effects: Phenomena such as stimulated Raman and Brillouin scattering can affect efficiency.

However, many of these challenges can be successfully overcome through appropriate measures such as optimizing materials and system parameters.

Future Prospects of Fiber Lasers

The continuous development of fiber laser technology is producing ever more powerful and efficient systems. Advances in miniaturization are enabling the use of compact lasers in new industries such as environmental technology and medical technology. With the integration of artificial intelligence and machine learning, future fiber lasers could offer even more precise and efficient applications.

Conclusion

fiber laser have established themselves as indispensable tools in numerous industries. Their efficiency, versatility and performance make them the preferred choice for applications in materials processing, biotechnology and telecommunications. With ongoing research and technological innovation, fiber lasers will continue to push the boundaries of what is possible and open up new fields of application.