Laser cleaning

Laser technology has made enormous progress in recent years. More compact and reliable lasers have found their way from the laboratory into trade and industry. An outstanding example of this is cleaning with pulsed Q-switched Nd:YAG lasers. Originally developed to restore valuable sculptures and monuments gently and with minimal substance, the Laser cleaning firmly established in monument preservation. This innovative technology is now also widely used in technical cleaning.

Pulsed lasers: precise cleaning without heat generation

The particular strength of lasers for cleaning tasks lies in their ultra-short light pulses. Pulsed Nd:YAG laser with pulse durations of less than 10 nanoseconds enable precise cleaning without heating up the underlying material. In contrast to continuous wave lasers, which generate heat, Q-switched lasers form a plasma when irradiated. This plasma expands explosively in the direction of the laser beam and removes dirt or covering layers. The extremely short exposure time minimizes heat transfer to the object. The cleaning process is even audible - a characteristic flaking of the unwanted layers. The Laser cleaning for high-contrast surfaces, for example dark dirt on light stones. Here the process stops automatically as soon as the absorbent layer is removed.

Laser cleaning: Success stories from Amiens to Dresden

The first major successes of the Laser cleaning was celebrated at the Cathedral of Amiens in France. Lasers have been used here for years to gently clean the artistic portals. Laser technology has also proven itself in the restoration of other important buildings such as the cathedrals of Rouen, Lille and Notre Dame in Paris.

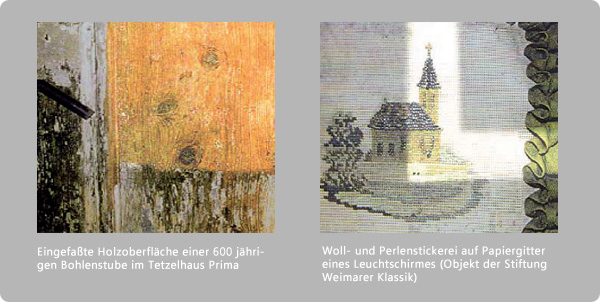

In Germany, the Laser cleaning a group of figures in the Great Garden in Dresden caused a stir. Further projects on marble figures in Potsdam Sanssouci and at the Jülich Citadel are already in progress. In addition to the gentle cleaning of stone, laser technology has also proven to be extremely effective on wood, fabric, ivory, paper, gold and bronze.

LT-300 Nd:YAG laser: Precise and gentle surface cleaning for industry and restoration

The LT-300 Nd:YAG laser is the ideal solution for the gentle and effective cleaning of a wide variety of surfaces. Pulsed laser beams effortlessly remove loosely bound covering layers without damaging the underlying material.

Versatile applications:

- Industry: Cleaning of molds, printing rollers, adhesive surfaces and more.

- Restoration: Gentle removal of dirt from valuable monuments, art objects and historical artifacts.

The technology: The LT-300 uses the power of micro shock waves that are created by the absorption of laser pulses. These waves remove dirt precisely without thermally stressing the object.

Cleaning Nd:YAG Laser LT-300

Cleaning of moldsPrinting rollersAdhesive surfaces RestorationContact: Dr. Wolf-Dieter Wagner