Thermal sensors are essential for the accurate measurement of laser power and energy. They work on the principle that radiant energy is absorbed and converted into heat. This causes a temperature rise in the absorber. The temperature difference between the hot area where the laser hits and a cool area where the heat is dissipated is measured using thermocouple arrays. These arrays are also known as thermopiles. In addition, each thermocouple generates a voltage. The total of these voltages is proportional to the incident laser power or energy.

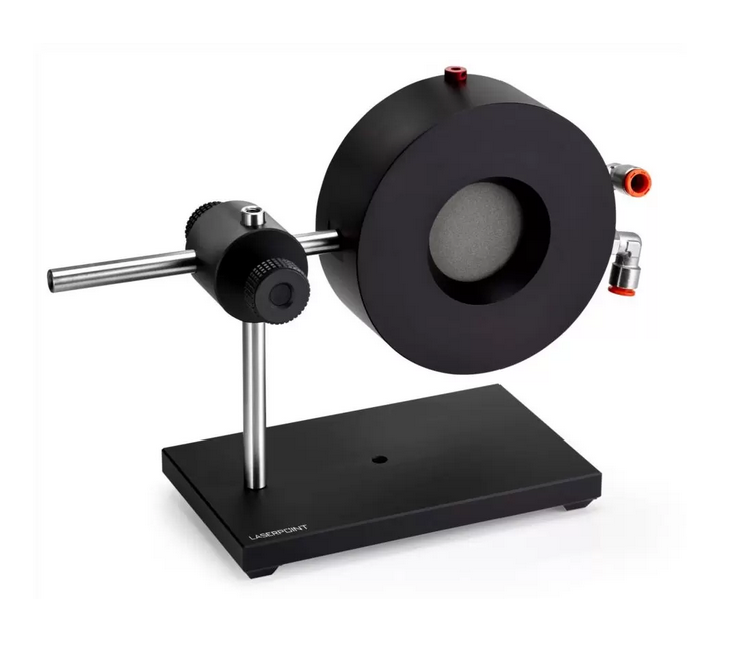

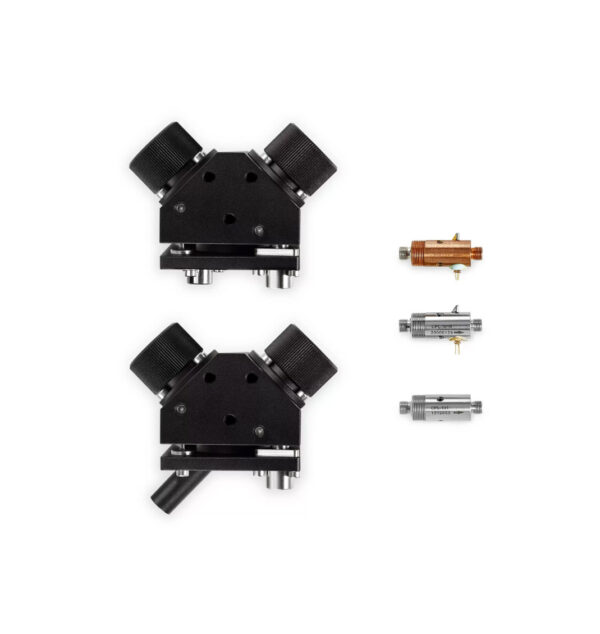

We offer various families of innovative detector heads from LaserPoint These are used to measure the power and energy of all lasers - from UV to far infrared. These products are therefore used in industry, medicine and science. They also enable precise long-term laser power measurements. Depending on the maximum measurable power, different cooling methods are used. These include convection, fan or water cooling. This ensures optimal measurement results.

Each power meter is supplied with a certificate confirming traceability to NIST and PTB. For maximum flexibility, our thermal sensors can be equipped with either a DB15 connection or with USB and RS-232 interfaces.

The thermal sensors are divided into the following categories (for different laser power):

Our power meters stand for innovation and quality. They are the result of years of research and development and meet the highest standards in laser power measurement. Trust in our expertise and optimize your laser applications with our reliable sensor solutions.

If you have any further questions about the systems, please feel free to send us a non-binding inquiry. Further information about the systems and all data sheets for each system variant can be found here: Laserpoint.eu